New Glasgow facility tests 3D-printed materials under space conditions to prevent dangerous space debris.

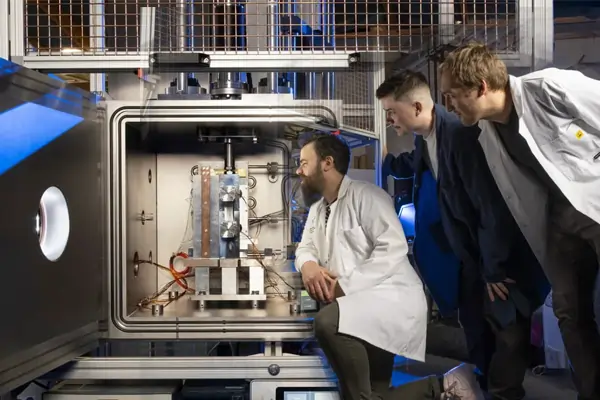

A team of researchers in Glasgow has created a special lab to test how strong 3D-printed materials are in space-like conditions. The NextSpace Testrig is the world's first laboratory of its kind. With assistance from the UK Space Agency, the James Watt School of Engineering at the University of Glasgow constructed it.

The use of 3D printing in space has the potential to change the construction of spacecraft, antennas and perhaps lunar dwellings. They may use specialized printers to print it directly in orbit rather than sending bulky equipment out from Earth. However, space is a hard environment with high temperatures and no air. Materials may be harmed by these circumstances, particularly if they have minute defects.

To make sure that 3D-printed components are safe for use in orbit, the NextSpace Testrig can test them in a vacuum room that simulates space. It can test the strength of materials by heating and cooling them between -150°C and +250°C and applying huge amount of loads of up to 2,000 kg.

If a poorly made part breaks in space, it could become dangerous debris. These pieces can travel as fast as bullets and damage other spacecraft or satellites. That’s why it's so important to test everything properly before printing in orbit.

Dr. Gilles Bailet, who led the project, says this new facility will help researchers and companies test their space materials more safely and efficiently. The data collected could also help set global safety standards for space manufacturing.

The project received £253,000 in funding and supports the UK’s growing space industry, especially in Glasgow, where many satellites are already built. This breakthrough puts the UK at the front of safer, smarter space manufacturing.

.webp)

.webp)

.webp)